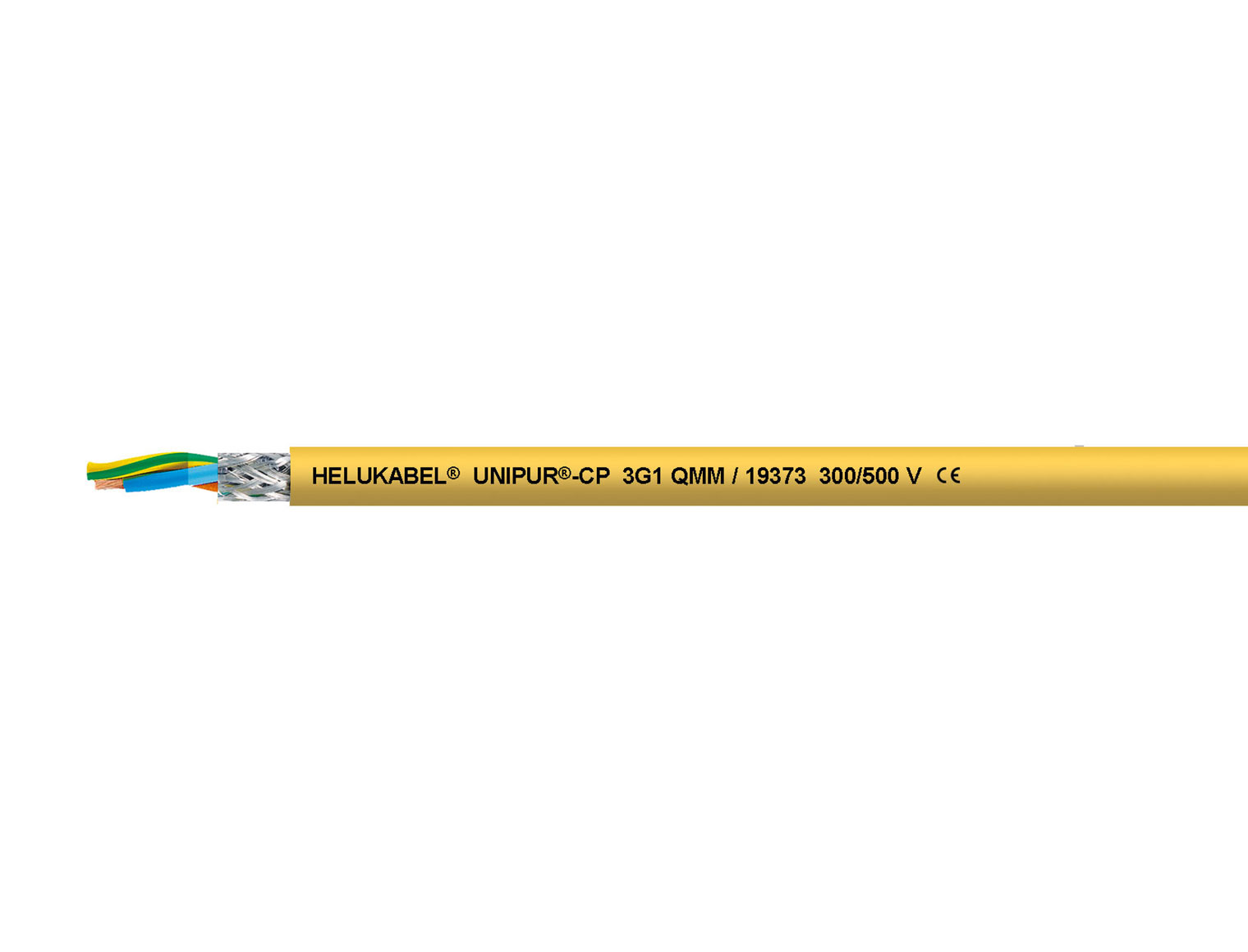

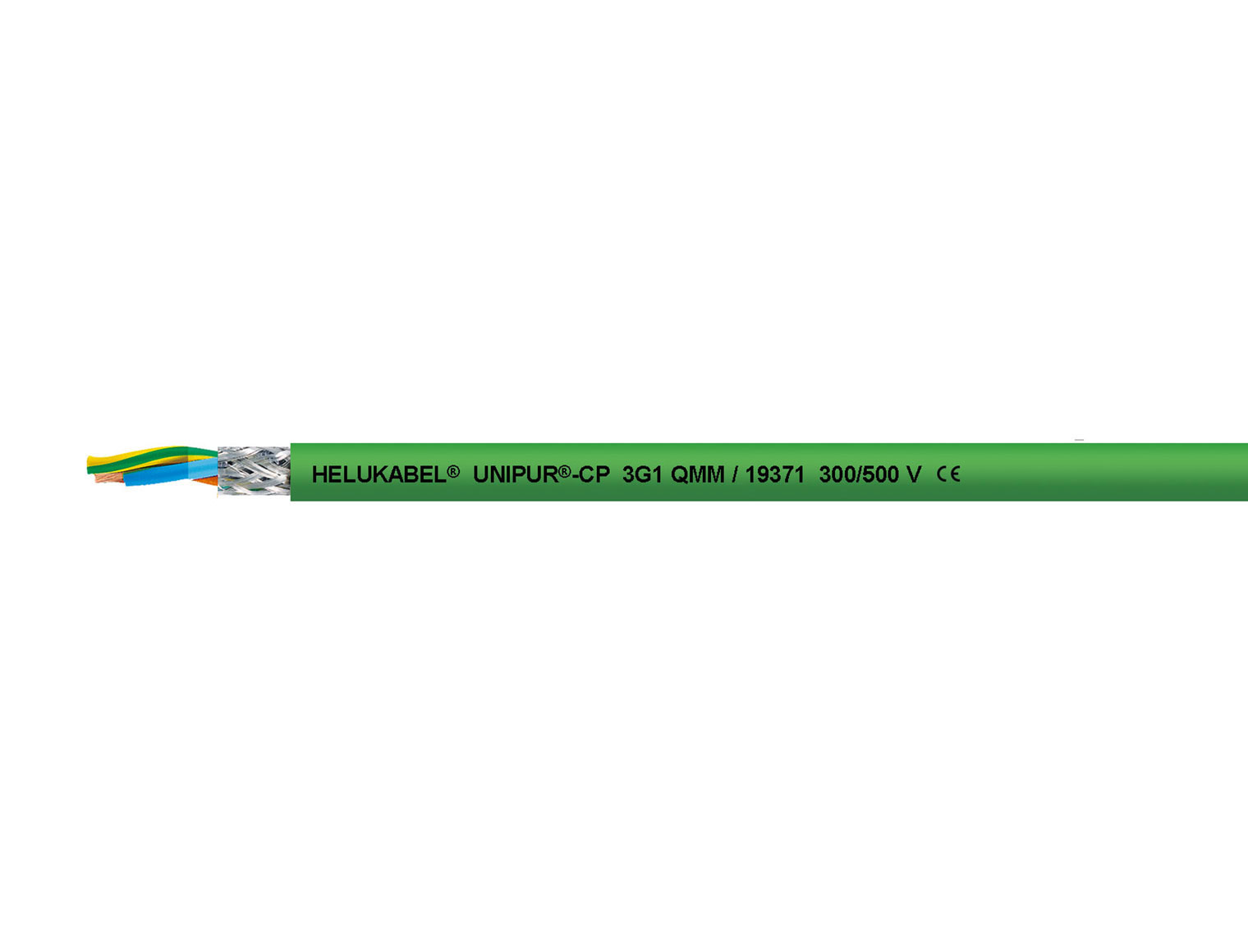

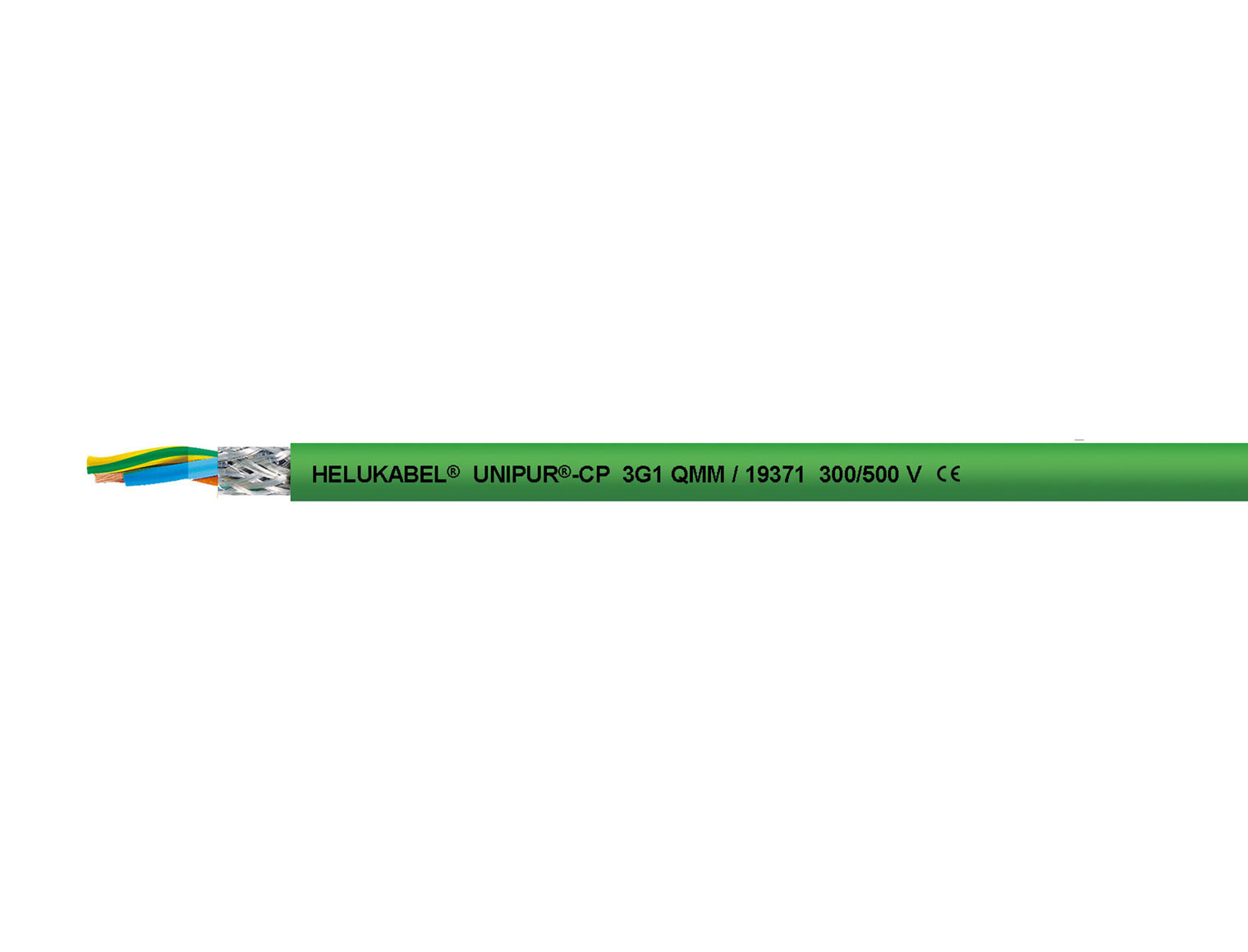

UNIPUR®-CP

- oil resistant

- flexible in cold temperatures

- highly abrasion-resistant

- notch, cut and wear resistant

- high compressive strength

- EMC-preferred type

- for outdoor use

- different outer sheath colours available from stock

Technical Data UNIPUR®-CP

| PUR control and connection cable in alignment with DIN VDE 0285-525-2-21 / DIN EN 50525-2-21 | |

| Temperature range | flexible -40°C to +90°C |

| Nominal voltage | 0.5 - 1 mm²: AC U0/U 300/500 V 1.5 - 16 mm²: AC U0/U 450/750 V |

| Test voltage core/core | 3000 V |

| Coupling resistance | at 30 MHz, approx. 250 Ohm/km |

| Minimum bending radius | flexible 12.5x Outer-Ø fixed 7.5x Outer-Ø |

Details UNIPUR®-CP

Cable Structure

-

- Copper wire bare, finely stranded acc. to DIN VDE 0295 Class 5 / IEC 60228 Class 5

-

- Core insulation: TPE

-

- Core identification acc. to DIN VDE 0293-308,

- 2 - 5 core(s): colour coded

- 6 - 41 core(s): black cores with consecutive labeling in white digits

-

- Protective conductor: starting with 3 cores,

- G = with protective conductor GN-YE, in the outer layer,

- x = without protective conductor

-

- Cores stranded in layers with optimal lay lengths

-

- Foil wrapping

-

- Screen: braided screen of tinned copper wires, approx. coverage 85%

-

- Outer sheath: Special grade of full polyurethane in alignment with DIN VDE 0207-363-10-2 / DIN EN 50363-10-2 (compound type TMPU)

-

- Sheath colour: see datasheet

-

- Length marking: in metres

Properties

-

- resistant to: oil, UV radiation, ozone, oxygen, weathering effects, hydrolysis, microbes, coolants, hydraulic fluids, acids, alkalis, greases, seawater and wastewater

-

- highly abrasion-resistant, notch-resistant, tear-resistant, cut-resistant, wear-resistant, low adhesion

-

- for outdoor use

-

- flexible in cold temperatures

-

- halogen-free

-

- the materials used during manufacturing are cadmium-free, contain no silicone and are free from substances harmful to the wetting properties of lacquers

Tests

-

- oil-resistant acc. to DIN VDE 0473-811-404 / DIN EN 60811-404 / IEC 60811-404

-

- UV-resistant acc. to DIN EN ISO 4892-2

-

- weather-resistant acc. to DIN EN ISO 4892-2

-

- certifications and approvals:

- EAC

Notes

-

- the conductor is metrically (mm²) constructed, AWG numbers are approximated, and are for reference only

Application

-

- Robust, flexible, screened cable with good abrasion, wear resistance and high pressure resistance for use in dry, damp and wet rooms, as well as outdoors. EMC = Electromagnetic Compatibility; in order to optimise EMC properties, we recommend a double-sided and all-round large contact area of the copper braiding. 1.5-16 mm²: When installed in pipes or similar closed systems, the cable is permitted for use up to and including 1000 V alternating voltage or 750 V direct voltage to earth.

Items UNIPUR®-CP

|

Item description

Part no.

|

Sheath colour | AWG (approx.) | Outer Ø mm (approx.) | Cu factor per km |

|---|

Downloads UNIPUR®-CP

Accessories

Products that match this product