PUR-C-PUR

- oil resistant PUR core insulation & PUR outer sheath

- highly abrasion-resistant

- notch, cut and wear resistant

- EMC-preferred type

- without an inner sheath

- for outdoor use

- robust control and connection cable for high mechanical stress in machine, tool and plant construction

Base price. Surcharges are added for metal, price increases, packaging, shipping and to reach minimum order values according to the General Terms & Conditions. For details, see shopping cart.

Technical Data PUR-C-PUR

| PUR control cable in alignment with DIN VDE 0285-525-1 / DIN EN 50525-1 | |

| Temperature range | fixed -40°C to +80°C |

| Nominal voltage | 0.75 - 1 mm²: AC U0/U 300/500 V 1.5 - 2.5 mm²: AC U0/U 450/750 V |

| Test voltage core/core | 0.75 - 1 mm²: 2000 V 1.5 - 2.5 mm²: 2500 V |

| Mutual capacitance core/core | at 800 Hz, approx. 150 pF/m |

| Mutual capacitance core/screen | at 800 Hz, approx. 320 pF/m |

| Coupling resistance | at 30 MHz, approx. 250 Ohm/km |

| Minimum bending radius | flexible 10x Outer-Ø fixed 5x Outer-Ø |

Details PUR-C-PUR

Cable Structure

-

- Copper wire bare, finely stranded acc. to DIN VDE 0295 Class 5 / IEC 60228 Class 5

-

- Core insulation: Special-PUR

-

- Core identification acc. to DIN VDE 0293-308,

- 2 - 5 core(s): colour coded

- 6 core(s): black cores with consecutive labeling in white digits

-

- Protective conductor: starting with 3 cores,

- G = with protective conductor GN-YE,

- x = without protective conductor

-

- Cores stranded with optimal lay lengths

-

- Foil wrapping

-

- Screen: braided screen of tinned copper wires, approx. coverage 85%

-

- Outer sheath: Special grade of full polyurethane acc. to DIN VDE 0207-363-10-2 / DIN EN 50363-10-2 (compound type TMPU)

-

- Sheath colour: grey (RAL 7032)

-

- Length marking: in metres

Properties

-

- resistant to: oil, UV radiation, ozone, oxygen, weathering effects, hydrolysis, microbes, coolants, hydraulic fluids, acids, alkalis, greases, seawater and wastewater

-

- highly abrasion-resistant, notch-resistant, tear-resistant, cut-resistant, wear-resistant, low adhesion

-

- for outdoor use

-

- flexible in cold temperatures

-

- halogen-free

-

- the materials used during manufacturing are cadmium-free, contain no silicone and are free from substances harmful to the wetting properties of lacquers

Tests

-

- oil-resistant acc. to DIN VDE 0473-811-404 / DIN EN 60811-404 / IEC 60811-404

-

- weather-resistant acc. to DIN EN ISO 4892-2

-

- certifications and approvals:

- EAC

Notes

-

- the conductor is metrically (mm²) constructed, AWG numbers are approximated, and are for reference only

Application

-

- Cable with copper shielding to prevent electromagnetic interference; particularly suitable as a data transfer and connection cable in machine and vehicle construction. Due to its mechanical, thermal and chemical properties, it has also proven itself under adverse weather and environmental conditions. EMC= Electromagnetic Compatibility; in order to optimise EMC properties, we recommend a double-sided and all-round large contact area of the copper braiding.

Items PUR-C-PUR

|

Item description

Part no.

|

AWG (approx.) | Outer Ø mm (approx.) | Cu factor per km | Weight kg/km (approx.) |

|---|

Downloads PUR-C-PUR

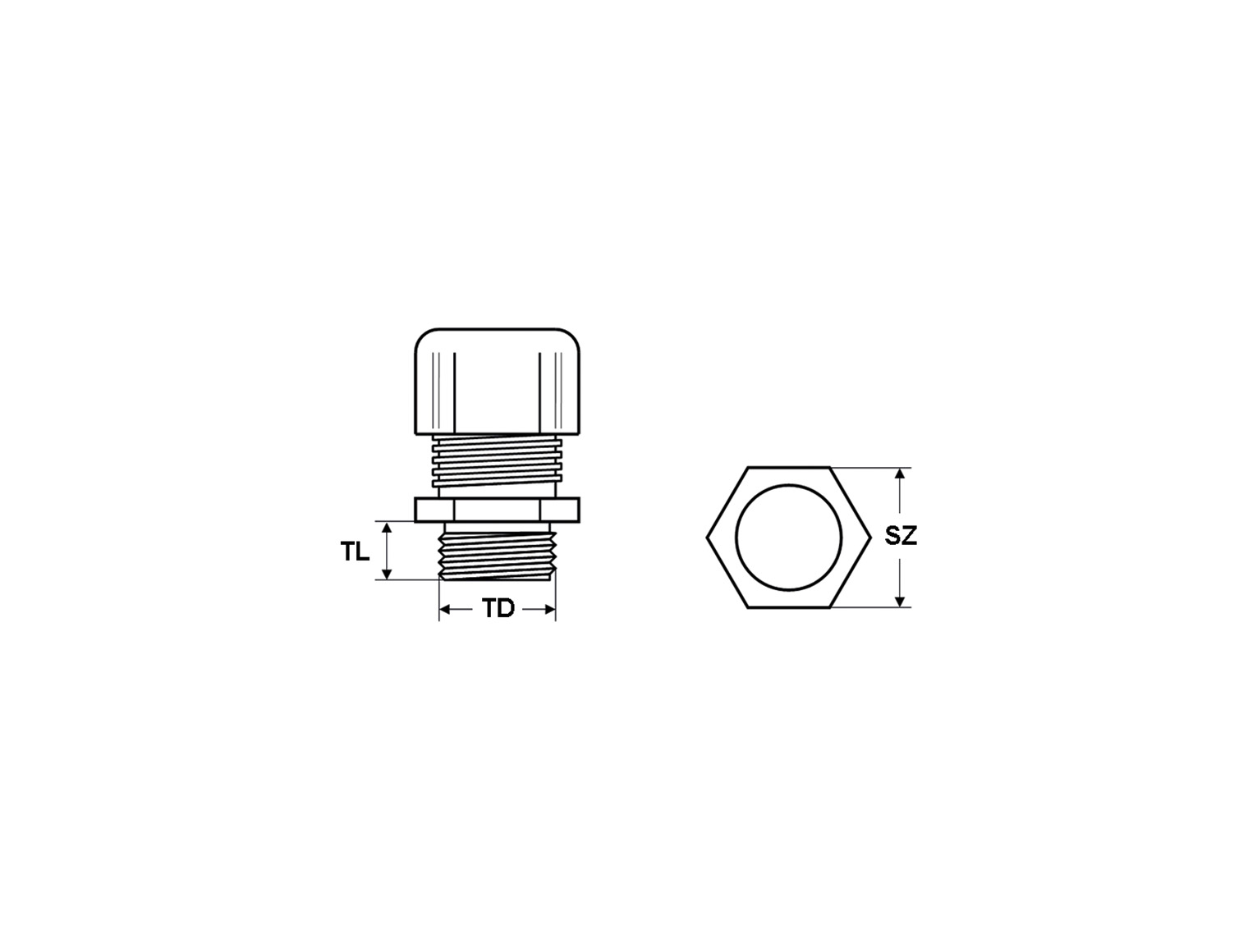

Accessories

Products that match this product