TOPFLEX®-EMV-3-PLUS-2YSLCY-J transparent 3 x 35 + 3 G 6 mm²

Part No. 22375

- double shielded

- improved EMC properties due to protective conductor (GN-YE) divided into thirds

- transparent outer jacket

Item Details TOPFLEX®-EMV-3-PLUS-2YSLCY-J transparent 3 x 35 + 3 G 6 mm²

- Part No.

- 22375

- Item description

- TOPFLEX®-EMV-3-PLUS-2YSLCY-J transparent 3 x 35 + 3 G 6 mm²

- AWG (approx.)

- 2

- Outer Ø mm (approx.)

- 26.9

- Cu factor per km

- 1535.0

- Weight kg/km (approx.)

- 1743.0

- Copper base in EUR / 100 kg

- 150

- Feet per Packaging Unit

- 1640, 3280

- Cut-to-length service available

- yes

- EAN/GTIN

- 4060892150487

- Customs tariff number

- 85444995

Technical Data TOPFLEX®-EMV-3-PLUS-2YSLCY-J transparent 3 x 35 + 3 G 6 mm²

| Motor connection cable for frequency converters in alignment with DIN VDE 0250 | |

| Temperature range | flexible +5°C to +70°C fixed -40°C to +70°C |

| Nominal voltage | AC U0/U 600/1000 V |

| Max. permissible operating voltage | alternating current (AC) conductor/ground 700 V three-phase alternating current (AC) conductor/conductor 1200 V direct current (DC) conductor/ground 900 V direct current (DC) conductor/conductor 1800 V |

| Test voltage conductor/conductor | 4000 V |

| Coupling resistance | see datasheet |

| Minimum bend radius | flexing <12 mm: 10x Outer ø flexing >12 mm: 15x Outer ø fixed 4x Outer ø |

Details TOPFLEX®-EMV-3-PLUS-2YSLCY-J transparent 3 x 35 + 3 G 6 mm²

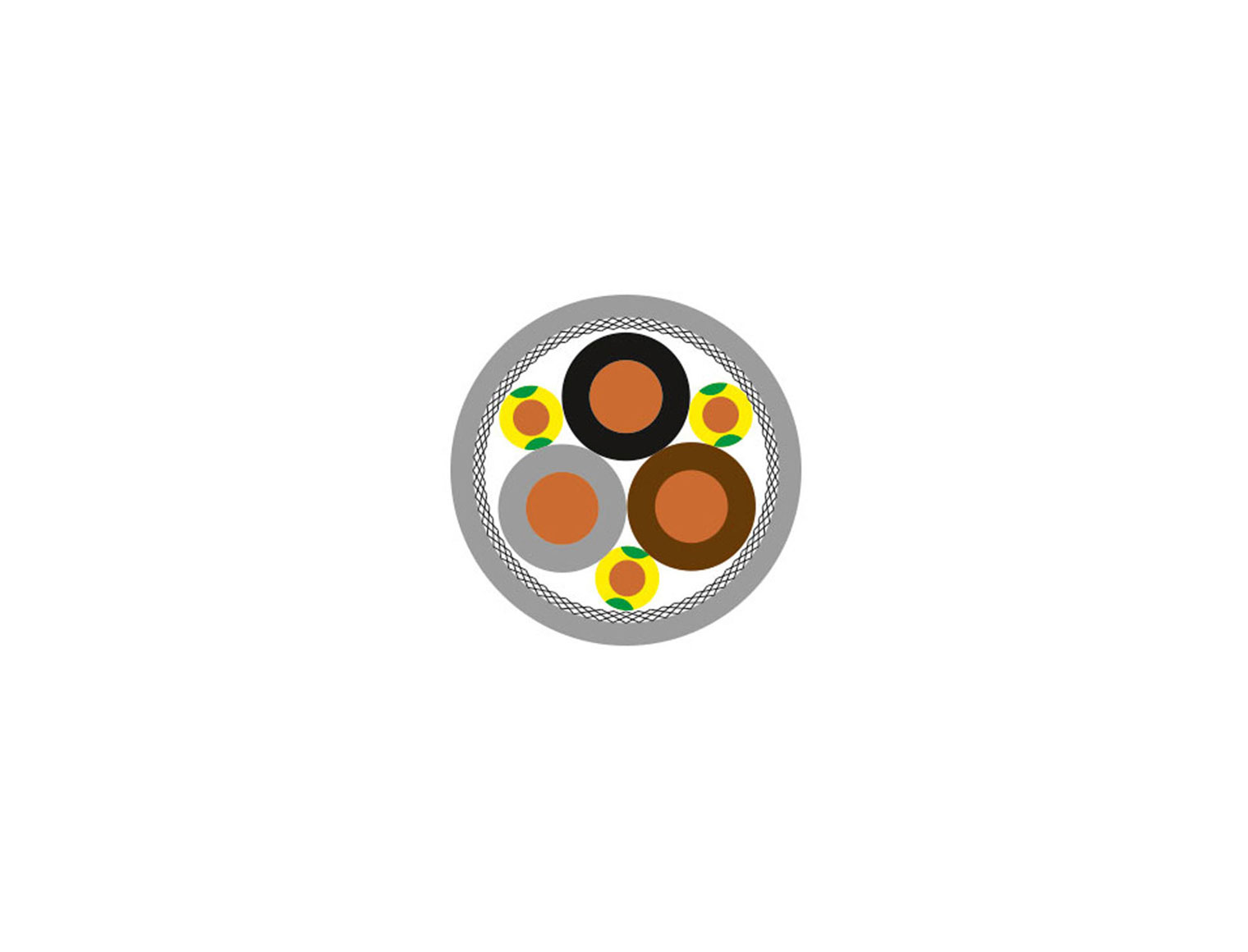

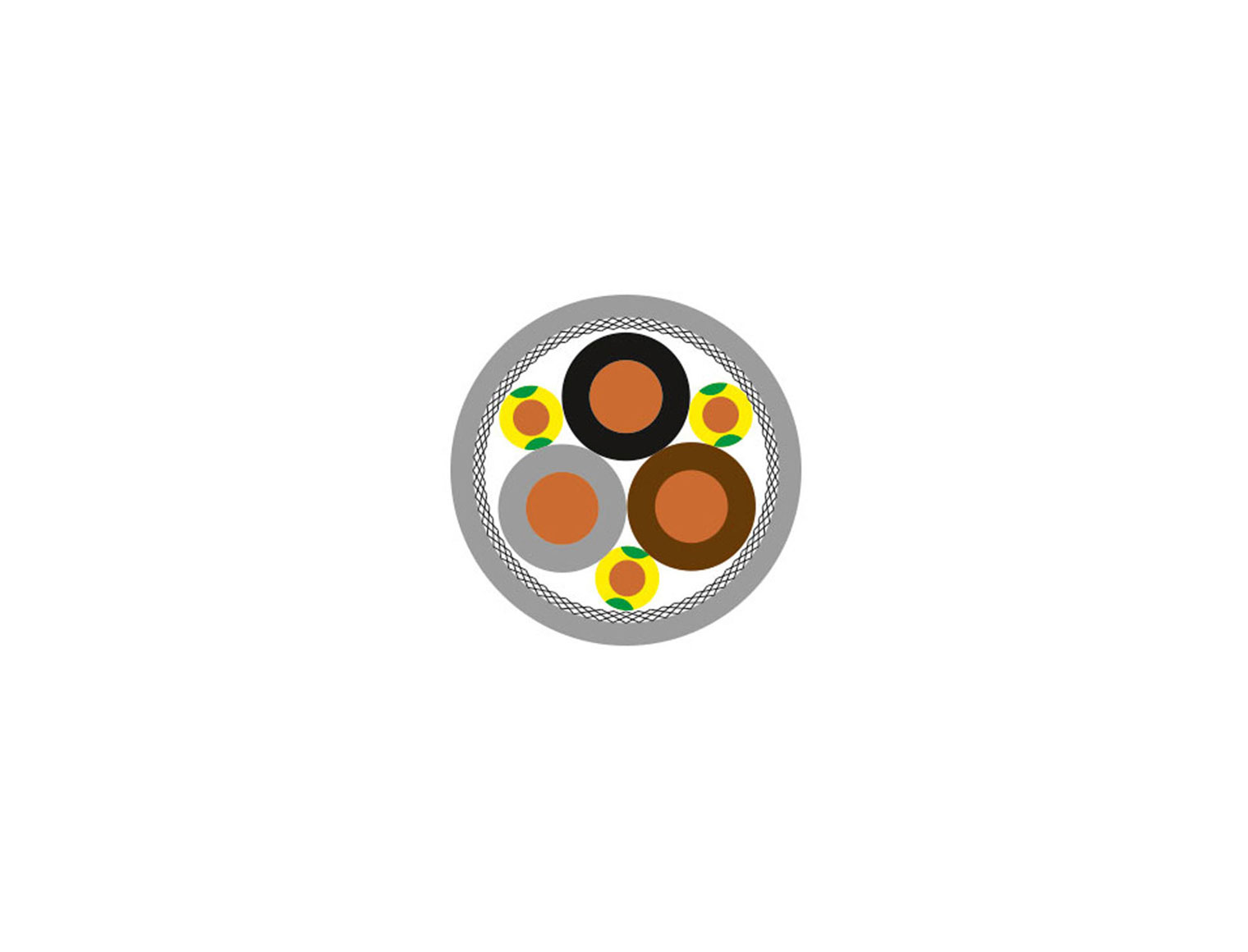

Cable Structure

-

- Copper wire bare, finely stranded acc. to DIN VDE 0295 Class 5 / IEC 60228 Class 5

-

- Conductor insulation: PE

-

- Conductor identification: brown, black, gray, green-yellow (divided into thirds)

-

- Ground conductor: GN-YE divided into thirds (3+3 conductor structure)

-

- Conductors stranded with optimal lay lengths

-

- 1. Shield: plastic-coated aluminum foil (St)

- 2. Shield: tinned copper braided shield, approx. coverage 85%

-

- Outer jacket: Special-PVC

-

- Jacket color: transparent

-

- Length marking: in meters

Properties

-

- optimal shielding enables interference-free operation of frequency converters

-

- low coupling resistance ensures good electromagnetic compatibility

-

- low mutual capacitance of the individual conductors due to PE conductor insulation and low shield capacity, enable low power transmission loss

Tests

-

- flame-retardant acc. to DIN VDE 0482-332-1-2 / DIN EN 60332-1-2 / IEC 60332-1-2

-

- electromagnetic compatibility acc. to DIN VDE 0875-11 / DIN EN 55011

-

- minimum cross section of 0.75 mm² meets requirements acc. to DIN EN 60204-1

-

- certifications and approvals:

- EAC

Notes

-

- the conductor is metrically (mm²) constructed, AWG numbers are approximated, and are for reference only

Application

-

- Used as a connecting cable for medium mechanical stress with fixed installation and occasional free movement in dry, damp or wet rooms, however, not suitable for outdoor use. Used in automotive, food, packaging and chemical industries, as well as in the environmental technology sector. EMC= Electromagnetic Compatibility; in order to optimise EMC properties, we recommend a double-sided and all-round large contact area of the copper braiding.