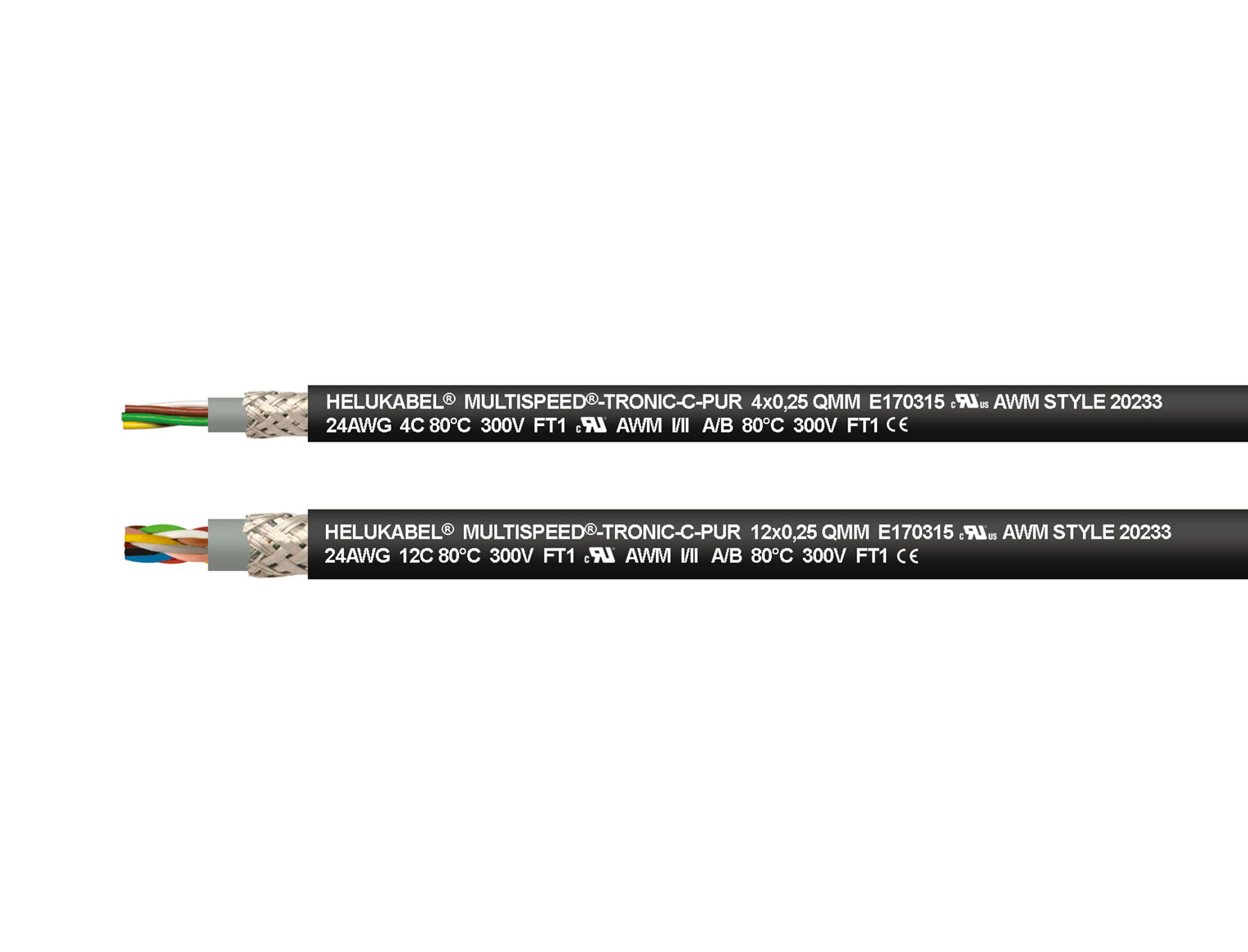

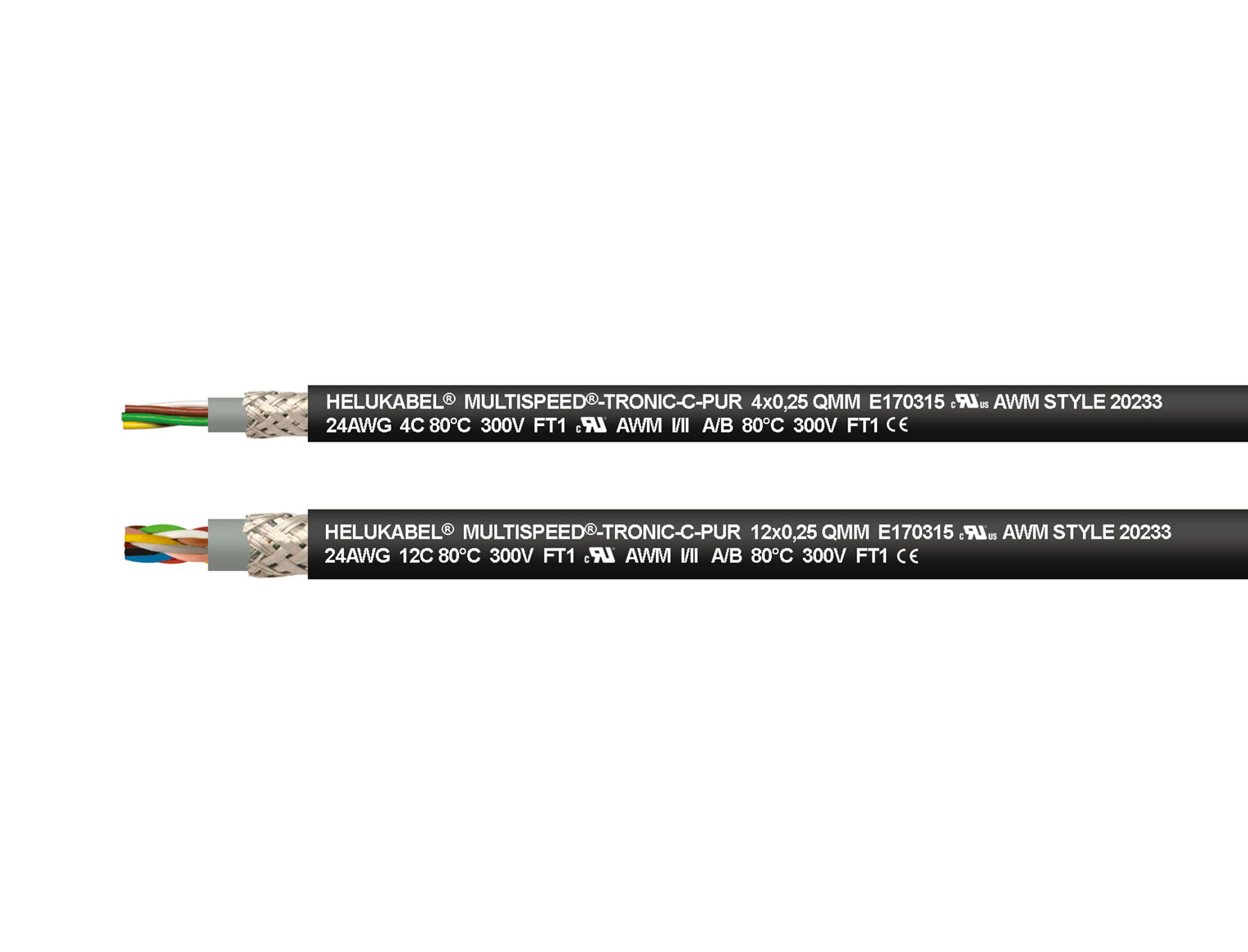

MULTISPEED®-TRONIC-C-PUR black 5 x 0.25 mm²

Part no. 24617

Item Details MULTISPEED®-TRONIC-C-PUR black 5 x 0.25 mm²

- Part no.

- 24617

- Item description

- MULTISPEED®-TRONIC-C-PUR black 5 x 0.25 mm²

- AWG (approx.)

- 24

- Outer Ø mm (approx.)

- 6.2

- Cu factor per km

- 26.0

- Weight kg/km (approx.)

- 68.0

- Copper base in EUR / 100 kg

- 150

- Metres per Packaging Unit

- 100, 305, 500, 1000

- Cut-to-length service available

- yes

- EAN / GTIN

- 4060892144578

- Customs tariff number

- 85444995

Technical Data MULTISPEED®-TRONIC-C-PUR black 5 x 0.25 mm²

| PUR drag chain cable acc. to UL-Std. 758 (AWM) Style 20233, CSA-Std. C22.2 No. 210 - AWM I/II A/B | |

| Temperature range | flexible -30°C to +80°C fixed -40°C to +80°C |

| Nominal voltage | UL (AWM) AC 300 V |

| Test voltage core/core | 3000 V |

| Coupling resistance | at 30 MHz, approx. 250 Ohm/km |

| Minimum bending radius | flexible 7.5x Outer-Ø fixed 4x Outer-Ø |

Details MULTISPEED®-TRONIC-C-PUR black 5 x 0.25 mm²

Cable Structure

-

- Copper wire bare, finely stranded, unilay with short lay lengths

-

- Core insulation: Special-PP

-

- Core identification acc. to DIN 47100, colour coded

-

- x = without protective conductor

-

- Stranding:

- 2 - 5 core(s): cores stranded into one layer with an optimally matched short lay length

- 7 - 25 core(s): cores stranded into bundles with optimally matched, short lay lengths; bundles stranded together around a tensile core

-

- Inner sheath: TPE, extruded filler

-

- Screen: braided screen of tinned copper wires, approx. coverage 85%

-

- Outer sheath: Special grade of full polyurethane acc. to DIN VDE 0207-363-10-2 / DIN EN 50363-10-2 (compound type TMPU)

-

- Sheath colour: black (RAL 9004)

-

- Length marking: in metres

Properties

-

- resistant to: oil, UV radiation, ozone, oxygen, weathering effects, hydrolysis, microbes, coolants, hydraulic fluids, acids, alkalis, greases, seawater and wastewater

-

- largely resistant to: chemicals

-

- highly abrasion-resistant, notch-resistant, tear-resistant, cut-resistant, wear-resistant, low adhesion

-

- for outdoor use

-

- suitable for use in drag chains

-

- highly restistant to alternate bending strength

-

- halogen-free

-

- the materials used during manufacturing are cadmium-free, contain no silicone and are free from substances harmful to the wetting properties of lacquers

Tests

-

- flame-retardant acc. to DIN VDE 0482-332-1-2 / DIN EN 60332-1-2 / IEC 60332-1-2, UL VW-1, CSA FT1

-

- oil-resistant acc. to DIN VDE 0473-811-404 / DIN EN 60811-404 / IEC 60811-404

-

- UV-resistant acc. to DIN EN ISO 4892-2

-

- weather-resistant acc. to DIN EN ISO 4892-2

-

- certifications and approvals:

- EAC

Notes

-

- the conductor is metrically (mm²) constructed, AWG numbers are approximated, and are for reference only

-

- for use in energy supply systems:

- 1) the assembly instructions must be observed

- 2) for further application parameters, please refer to the selection tables

- 3) for special applications, we recommend contacting us and using our data entry form for energy supply systems

Application

-

- For continuous operation in drag chains with long traverse paths and high as well as low speeds of movement; for installation in dry, moist and wet rooms as well as outdoors. This drag chain cable is particularly robust and abrasion resistant and used where highest requirements in regards to flexibility and resilience are imposed. As a screened cable, it allows interference-free transmission of data and signals in measurement and control technology applications. EMC= Electromagnetic compatibillity; to optimize the EMC features we recommend a large round contact of the copper braiding on both ends.