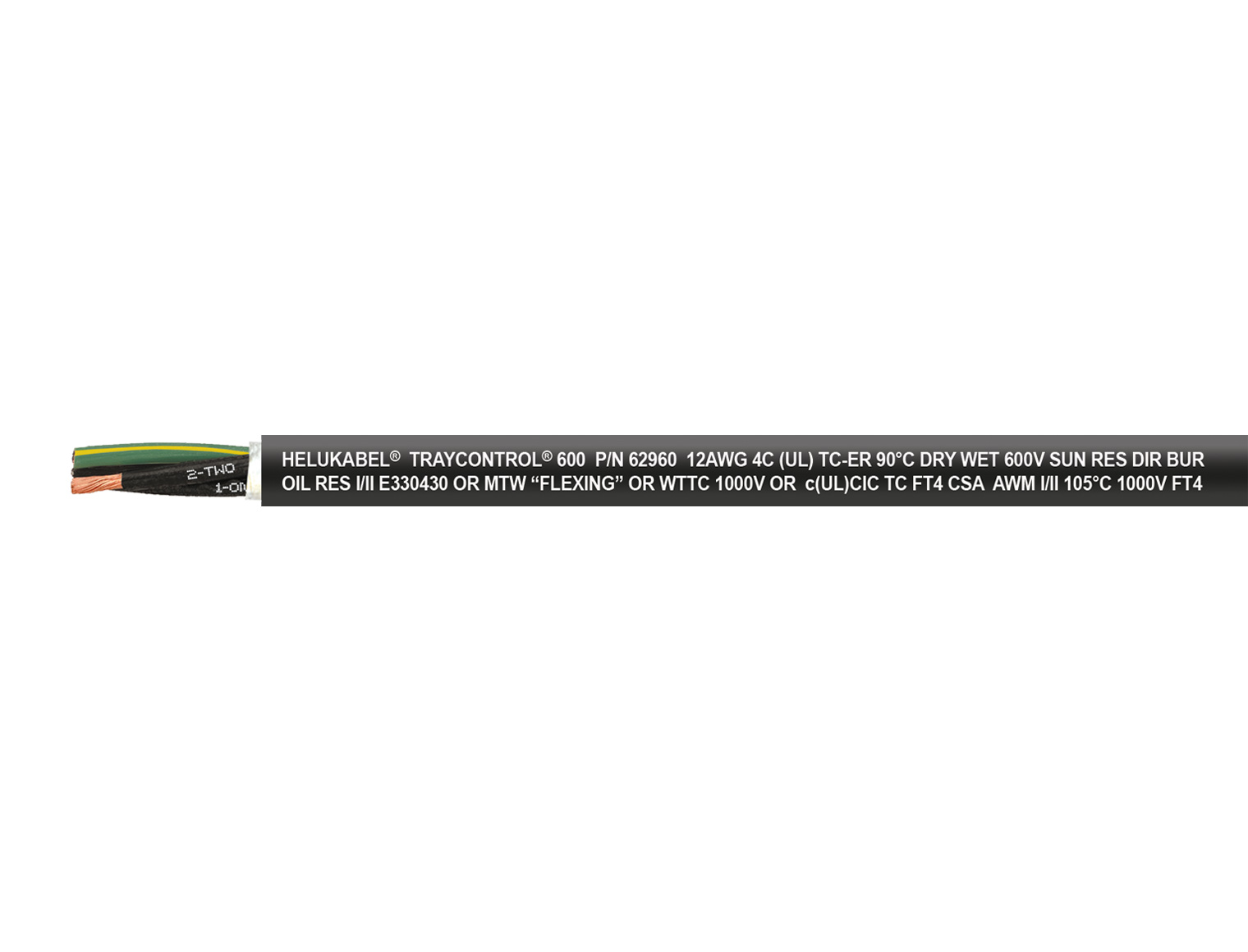

TRAYCONTROL® 600 black 2 x 12 AWG

Part No. 62958

Item Details TRAYCONTROL® 600 black 2 x 12 AWG

- Part No.

- 62958

- Item description

- TRAYCONTROL® 600 black 2 x 12 AWG

- Outer Ø mm (approx.)

- 9.7

- Cu-weight kg/km

- 63.6

- Weight kg/km (approx.)

- 137.0

- Copper base in EUR / 100 kg

- 150

- VPE/m

- 100, 500, 1000

- Cut-to-length service available

- yes

- EAN/GTIN

- 4060892017483

- Customs tariff number

- 85444995

Technical Data TRAYCONTROL® 600 black 2 x 12 AWG

| PVC control and connection cable acc. to UL-Std. 1063 (MTW), CSA-Std. C22.2 No. 210 - AWM I/II A/B, 20 AWG - 12 AWG: UL-Std. 2250 (ITC-ER), UL-Std. 13 (PLTC-ER), 18 AWG - 4/0 AWG: CSA-Std. C22.2 No. 230 & 239 - c(UL) CIC-TC, 18 AWG - 500 kcmil: UL-Std. 1277 (TC-ER), UL-Std. 2277 (WTTC), UL-Std. 1690 (DP-1) | |

| Temperature range | flexible +5°C to +50°C fixed -25°C to +105°C UL (TC) to +90°C |

| Nominal voltage | UL (TC) AC 600 V UL (WTTC) AC 1000 V UL (MTW) AC 600 V CIC-TC AC 600 V |

| Test voltage core/core | 3000 V |

| Minimum bending radius | flexible 5x Outer-Ø |

Details TRAYCONTROL® 600 black 2 x 12 AWG

Cable Structure

-

- Copper wire bare, finely stranded, Class K / AWG sizes

-

- Core insulation: Special-PVC, with transparent nylon jacket

-

- Core identification: black cores with consecutive labeling in white digits

-

- Protective conductor: starting with 3 cores,

- G = with protective conductor GN-YE, in the outer layer,

- x = without protective conductor

-

- Cores stranded in layers with optimal lay lengths

-

- Fleece wrapping

-

- Outer sheath: Special-PVC

-

- Sheath colour: black (RAL 9005)

-

- Length marking: in feet

Properties

-

- resistant to: oil, UV radiation (SUN RES)

-

- for outdoor use

-

- direct burial (DIR BUR)

-

- the materials used during manufacturing are cadmium-free, contain no silicone and are free from substances harmful to the wetting properties of lacquers

Tests

-

- oil-resistant acc. to UL Std 1277 Tab. 12.2, Oil Res I / Oil Res II

-

- Cold Bend Test acc. to UL Std. 1277 No. 17

-

- Cold-Impact Test (-40C) acc. to UL Std. 1277 No. 18 / UL Std. 1581 No. 593

-

- Impact Test (-ER) acc. to UL Std. 1277 No. 23

-

- Crushing Test (-ER) acc. to UL Std. 1277 No. 24

-

- direct burial (DIR BUR) acc. to UL Std. 1277 No. 5 (wet-locations insulation), No. 19 (crushing test)

-

- Vertical-Tray Flame Test (FT4) acc. to UL Std. 1277 No. 15 / UL Std. 1685, CSA-Std. C22.2 No. 2256

-

- certifications and approvals:

- EAC

- ECOLAB®

- for Class 1 Div. 2 explosive environments acc. to NEC Art. 501

Notes

-

- Conductor sizes are based on the AWG measurement system, metric conductor sizes (mm²) are approximated and are for reference only

Application

-

- Flexible, oil-resistant control and power cable for up to 600 V (WTTC 1000 V); the special combination of TC-ER, PLTC-ER and ITC-ER allows this cable to be used in machines throughout industrial plants, according to NFPA 79. Its exceptional abrasion resistance and outstanding oil resistance (Oil Res I/II) ensures a long service life in dry, damp and wet industrial environments. Suitable for underground, and open, unprotected installation from the cable tray to machines in industrial plants. Recommended applications: production lines, machine building, switch cabinets, conveyor systems, packaging machines, bottling plants and automotive manufacturing facilities.